- Structured Cost Excellence Program integrates R&D, procurement, manufacturing, and supply chain.

- Best-cost country sourcing and cost optimization enhance efficiency.

- Supplier collaboration delivers innovation.

- Dual focus on cost leadership and customer centricity underpins sustainable competitiveness and growth.

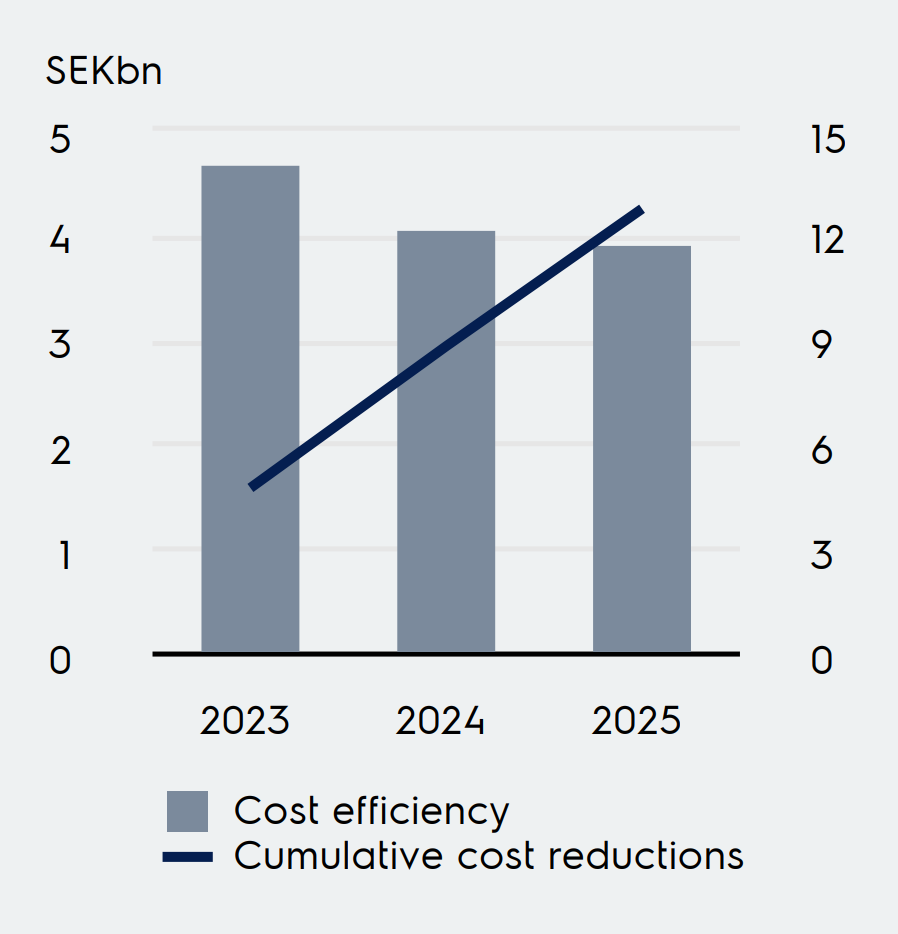

Cost leadership is a fundamental pillar of Electrolux Group’s long‑term competitiveness, profitability, and growth. In 2025, cost reductions of SEK 4bn were delivered, following SEK 4bn in 2024. While previous savings stemmed largely from organizational simplification, focus in 2025, and going forward, centers on product cost reductions, optimized sourcing and industrial efficiency.