LABOR PRACTICES

MANAGEMENT APPROACH

A sustainable approach starts at home, with safe workplaces, mutual respect and common values. The Group’s values and foundation helps Electrolux realize this approach and comprises both operational and core values.

Achievements and objectives

For achievements and objectives regarding labor practices, refer to the performance reviews of People and operations (Ethical Business), performance reviews of Stakeholders and society (Responsible sourcing) and to Community for insights into shifting production to low-cost regions.

Values, codes and policies

The Electrolux Foundation, or the Group’s operational values, affirms the corporate culture and commitment to sound and universal ethical business practices. They are defined as ethics, integrity, respect, diversity, safety and sustainability. Electrolux aligns its management of labor and human rights with the Foundation through Group codes and policies, both internally and along the supply chain.

Relevant codes include the Electrolux Code of Ethics and the Code of Conduct (CoC), supported by the Workplace Standard. The Standard outlines mandatory practice to ensure CoC compliance. All sustainability-related policies and procedures affirm the Group’s endorsement of the UN Global Compact principles on human rights, labor, the environment and anti-corruption. The CoC and Workplace Standard apply in equal measure to own operations and along the supply chain. In 2013, the CoC and Workplace Standard were under revision, with planned approval and launch in 2014.

Electrolux has a number of ways of ensuring that the Code of Conduct is fulfilled within its operations and along the value chain.

- ALFA assessments of the CoC.

- Internal audits of the CoC.

- Global audits of ISO standards for environment and OHSAS certification for health and safety aspects of the CoC.

- Ethics at Electrolux program.

- Awareness raising on the Electrolux Foundation, integrated into Human Resource processes and training.

- Responsible sourcing audits and capacity building along direct material suppliers and OEM partners.

- Evaluations of CoC performance of new suppliers.

Responsibility

As each unit’s line management has particular responsibility for active implementation of the CoC and Workplace Standard, they play a crucial role in implementation. This includes communicating CoC requirements within their unit on a regular basis through training and annually assessing the unit’s CoC performance. Responsibility also includes ensuring that practices and processes align with the CoC. Suppliers are required to uphold the same standards, and are audited, based on risk of non-compliance, as described in the Human Rights section of this report.

Training and awareness

Responsibility for CoC training and awareness also rests with local line management. Performance is followed up through the CoC audit program.

As described further in Ethics at Electrolux, is an ethics program comprising a training module and a locally based Helpline. It uses scenarios to explore ethical dilemmas employees may encounter in their work. The program is organized through Human Resources in each business sector, with the support of Group Legal, Sustainability Affairs and the internal audit function (MA SA).

To support the introduction of the anti-trust policy and accompanying guidelines, and the relaunch of the Anticorruption Policy, live training on antitrust and anticorruption issues took place during 2012-2013 in all regions.

The Purpose is a program that encourages all employees in the company to contribute to developing smart, resource-efficient solutions, and creating value beyond market and financial objectives. It has also been a means to support integration of the sustainability strategy. In 2013, approximately 150 voluntary workshops engaging 2,400 employees were held across the company. The program will continue in 2014.

Monitoring and follow-up

The CoC assessment (known as Awareness-Learning-Feedback-Assessment – ALFA) is carried out annually. Its purpose is to:

- Ensure that line managers understand what is expected of them

- Assess the level of CoC implementation.

- Survey progress in implementing new requirements.

The assessment helps ensure management attention to the CoC and Workplace Standard and identifies improvement areas. All 57 manufacturing units were included in the 2013 ALFA assessment.

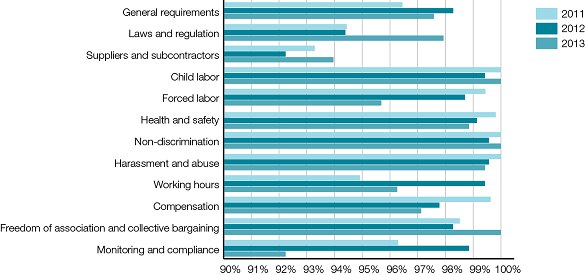

ALFA assessments of the Code of Conduct

Internal Code of Conduct Audits

In addition to the broad overview given by ALFA assessments, the tailored internal CoC audit program is designed to achieve a deeper understanding of CoC compliance.

As outlined in Mapping and addressing human rights risks, the selection process for auditing is based on factors such as the human rights risk level of the country, historic audit performance of the unit, Helpline calls, customer requests and the nature of activities. In 2013, 20 (18) of 26 (28) plants were audited. The outcome indicates a sharp reduction in the number of non-compliances—185 compared to 301 non-compliances in 2012. This improvement is due in large part to compliance improvement at Olympic factories in Egypt.

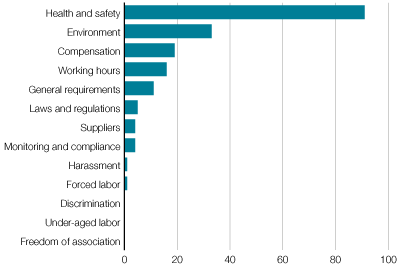

The findings form the basis of required action plans that are followed up with the sites. Follow-up audits are planned for sites with a high number of significant findings. The majority of findings are related to environment and occupational health and safety.

Internal Code of Conduct Audit findings

Additionally, the global ISO certification program for environment and quality began in 2013 and encompasses annual audits of all manufacturing facilities, with recertification audits every third year. For selected sites, the audits also cover OHSAS for health and safety. In parallel, the Group conducted third-party CoC audits for high-risk areas.

Employment

In markets increasingly vying for top talent, continual alignment to business priorities is the key focus area for talent management. Electrolux has a group-wide plan—the people plan—that will help realize the company ambition to find the right people in the right jobs, and thereby support execution of the business strategy. In 2014, the plan will evolve to focus on three core priorities:

- Develop strong talent pools in business critical functions

- Transform HR toward business HR

- Develop high performing learning organization

The plan promotes strong leadership aligned with the business strategy, focusing on building a learning organization and strengthening capabilities and competences in prioritized areas. Electrolux has group-wide processes in place to achieve alignment in the appraisals to measure performance.

Electrolux has various human resource-related policies in addition to Codes and standards. They include the Appointment of Senior Managers Policy, the Recruitment and Internal Transfer Policy, and the Grandparent principle—all designed to ensure fair and transparent hiring practices—as well as the Compensation Policy and Pension and Other Benefits Policy, defining a consistent approach to remuneration.

In addition, the Group applies tools for leadership development, talent management and succession mapping to manage human resources long-term.

Labor and management relations

A new global Industrial Relations Strategy was defined this year, for implementation in 2014. Dialog with international unions such as IndustriAll and IF Metall, learnings from experience in emerging markets and dialog with investors informed the strategy process.

LA 2 and 4: Rate of employee turnover and collective bargaining coverage

|

|

2013 | 2012 | 2011 | 2010 | 2009 |

|---|---|---|---|---|---|

| Total emplyees - Male 1) | 33,195 | 41,053 |

|

27,997 | 32,955 |

| Total employees - Female 1) | 16,800 | 18,425 |

|

15,404 | 17,678 |

| Employee turnover - All employees (%) 1) | 14% | 12% | 20% | 16% | 17% |

| Employee turnover - Male (%) 1) | 16% | 12% | 23% | 18% | 18% |

| Employee turnover - Female (%) 1) | 12% | 12% | 15% | 12% |

|

|

|

|

|

|

|

|

| LA4 Employees covered by collective bargaining (%) 2) | 63% | 63% | 68% | 69% | 76% |

2) Employees at production facilities covered by collective bargaining agreement. 26,889 of 42,357 employees at 57 production facilities were covered by collective bargaining agreements.

As regulated by Swedish law, labor relations starts at the top. The Board of Directors comprises non-executive members, the President and three employee representatives together with their three deputies. Labor relations are primarily managed at the national and local-site levels in accordance with the CoC and Workplace Standard.

The CoC stipulates that all Electrolux employees are free to exercise their legal rights to form, join or refrain from joining organizations representing their interests as employees. In addition, Electrolux insists that all operations and those of its suppliers respect employees’ right to collective bargaining. The revised CoC will be further aligned with OECD Guidelines for Multi-national Enterprises and ILO core conventions in these regards.

Swedish Board union representatives visit select regions within the Electrolux sphere on a needs basis to educate local union representatives and share best practice on union work.

Workers’ forums

In those regions where worker associations are not possible or not yet fully developed due to national praxis, each unit and supplier is expected to find appropriate and legal mechanisms through which workers can effectively express workplace concerns to management. Records are to be kept from these formalized consultations and made available upon request.

Freedom of association provisions include parallel means, which are to be put in place in countries where the right to freedom of association and collective bargaining is restricted. Every unit must have mechanisms in place to ensure that workers can express their concerns to management and that records are kept from formalized consultations.

As of 2010, Electrolux has an International Framework Agreement (IFA)] in place, signed together with the Swedish trade unions IF Metall, Unionen and the federation formerly known as the International Metalworkers Union (IMF). Through this, Electrolux and key unions underline the Group’s commitment to maintain the same standards in all the countries where it operates, and specifying core ILO conventions.

In fulfillment of agreements, CoC compliance is reviewed and discussed with employee representatives on an ad hoc and annual basis. Dialog covers outcomes of the CoC assessments and internal audits, an overview of cases reported through the Ethics Helpline and general improvement areas.

Occupational health & safety

The group-wide accident rate was reduced by 10% (10) this year, taking the company a few steps closer to realizing its vision of accident-free facilities. This data encompasses all Group factories, warehouses and newly acquired operations.

The Group’s work with OHS primarily focuses on the safety of workers in production and secondly to raise awareness on health and wellbeing of office workers.

All employees in production are covered by an OHS management system, with Major and Small Appliances covered by an OHS management system coordinated through Global Operations. Global Operations is tasked with standardizing production and improving production processes and has a long-term goal to operate 25% of its plants at OHS best practice levels (TCIR of less than 0.25) by 2015. At present, approximately 20% of Global Operations’ factories have reached this goal.

Electrolux Professional, consisting of some 2,600 (2,600) employees, has its own program aligned with Group ambitions, yet tailored to operational challenges of dealing with more hand-crafted products. Performance is disclosed in group-wide data collection.

Forward focus

Within Global Operations, each manufacturing facility develops a one-to-three year safety action plan based on minimum global standards. Each month, the management team at each facility meets with employees to review safety and environmental incidents and develop prevention actions. They identify both risks on site and mitigation plans.

A global safety team is responsible for the development and implementation of the health and safety recording system. It collects safety statistics and incident reports for every manufacturing facility on a monthly basis, thereby identifying commonalities between production groups, regions and by product line.

Another focus is on setting minimum standards for high-risk tasks across the business.

Safety training and awareness

Global Safety Day, designed to engage employees and demonstrate management commitment, is an increasingly important event in factory calendars, where ‘best performing’ and ‘most improved’ regional facilities are recognized. Global Safety Day is part of a larger plan to increase performance at all plants. Each facility has developed a plan to contribute to the group-wide goal. The overriding aim is to prevent injuries and environmental incidents from occurring in the first place.

In 2013, Electrolux piloted the integration of the Employee Engagement Survey among production workers in four factories. Included in the survey were questions that measured safety awareness levels and areas requiring improvement. The outcome of the pilot indicated satisfactory safety awareness levels among production workers As of 2014, the group-wide EES will measure safety awareness levels among all factory workers.

StopSearchHereCEO Statement

In 2013 we continued to deliver above our growth target and delivered 4.5% in organic sales growth.

CEO Statement

I'm convinced that raising product efficiency for the growing middle class is where long-term shareholder value creation lies.

Our products

Electrolux is the only appliance manufacturer in the industry to offer complete solutions for both consumers and professionals. The focus is on innovative and energy-efficient products in the premium segments.

Sustainability

Achieving the Group's vision of sustainability leadership is crucial to realizing the business strategy. The objective is to develop smarter, more accessible, resource-efficient solutions that meet people's needs and improve their lives. Read the comprehensive sustainability performance review.

Awards & recognition

Financial Reporting

Net sales for the Electrolux Group in 2013 amounted to SEK 109,151m, as against SEK 109,994m in the previous year. The organic sales growth was 4.5%, while currencies had an impact of -5.3%.