Occupational health and safety

LA6-9

Manufacturing facilities have been the focus of the Group’s health and safety (OHS) work since stepping up efforts four years ago.

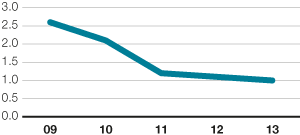

With a Group accident frequency rate (TCIR) of 1.0 (1.1), almost 65% of factories across the company have achieved below 1.0; considered good OHS performance in the manufacturing industry. Progress over time is more noteworthy - the 2013 rate was reduced by a further 10% compared to 2012 and 62% compared to 2009.

On target

Electrolux is rolling out a global health and safety management system for all Major Appliance facilities and three of four Small Appliance factories with the aim to share safety best practice. The system is expected to be fully in place by mid-year 2014, when it will be integrated into acquired operations. The goal is to operate 25% of Major Appliance facilities at industry best practice levels (TCIR of less than 0.25), and by 2015 to reach a goal of 0.7. Global operations is on track to achieve this. Work towards the target continues. While 2012 performance exceeded this goal, integration of performance data from Argentina, Chile and Egypt in 2013 required realignment to the target.

Year-on-year targets have also been set for factories. Facilities with TCIRs greater than 1.0 are expected to demonstrate a 10% improvement on OHS incidents while those under 1.0 are expected to reduce their rates by 5%. These goals have been met.

More than in any other area, there was a marked improvement of OHS performance in the CTI plants in Chile and Argentina, with a 50% decrease in the injury frequency.

In production environments, changing behavior is crucial to reducing OHS risks. That is why objectives should be communicated in a way that resonates with people on the factory floor. Electrolux launched the 100 days without an accident program in 2013 to engage everybody in OHS objectives.

In order to better understand the types of incidents that occur in factories and prevent them from recurring, Electrolux also introduced “First Aid Incident Rate” (FAIR) in 2013 to measure near misses, and incidents that only required first aid. In 2014, the KPI will be accompanied by a target.

Joint OHS committees

The Workplace Standard and CoC stipulate that local OHS management must live up to Group standards. To ensure this, an OHS Committee, consisting of both management and workers, must be in place at every manufacturing facility. The committees are intended to engage both workers and management in achieving objectives, monitoring performance and advising on OHS programs. This year, these committees covered 96% of employees at manufacturing units. ALFA assessments indicate that two of 57 reporting facilities lack a committee and have committed to remedy this in 2014.

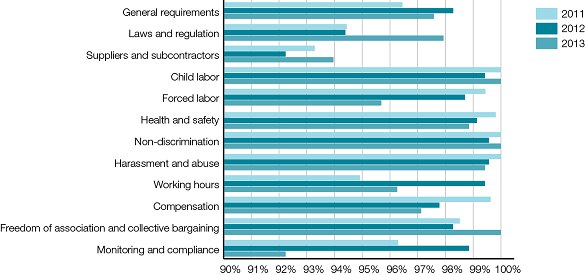

ALFA assessments of the Code of Conduct.

Rates of injury

In 2013, the global incident rate decreased by 10% (10) while the number of workdays lost due to injuries decreased by 48% (36) compared to 2012. Local definitions on what constitutes a workplace injury have been used to determine the total injury rate.

LA 7: Rates of injury

Education and training

There is strong group-wide focus on training in order to prevent injuries and illnesses. Global OHS training is ongoing and includes induction, CPR, first aid, driver-awareness, drugs and alcohol, and safe operating of machinery such as forklifts.

The 2013 Global Safety Day demonstrates commitment and builds awareness about the importance of safety in the workplace and rewarded facilities in each region for outstanding health and safety performance and improvements.

Coverage in trade union agreements

The International Framework Agreement, a formal agreement between Electrolux and key unions underlines the Group’s commitment to maintain the same standards in all the countries where it operates. The agreement encompasses a chapter regarding OHS, stating that all employees are to be provided with a safe and healthy working environment, and, when applicable, safe and healthy residential facilities with meeting local law as a minimum. Electrolux and its suppliers are also responsible for taking appropriate action to prevent workplace accidents or illnesses as defined in the Workplace Standard.

Safety mindset shift in Argentina

The factory in Rosario, Argentina demonstrated a step-change in safety performance after the introduction of the Group’s safety program. No small accomplishment, they realized a 68% reduction in accidents in the span of a year.

CEO Statement

In 2013 we continued to deliver above our growth target and delivered 4.5% in organic sales growth.

CEO Statement

I'm convinced that raising product efficiency for the growing middle class is where long-term shareholder value creation lies.

Our products

Electrolux is the only appliance manufacturer in the industry to offer complete solutions for both consumers and professionals. The focus is on innovative and energy-efficient products in the premium segments.

Sustainability

Achieving the Group's vision of sustainability leadership is crucial to realizing the business strategy. The objective is to develop smarter, more accessible, resource-efficient solutions that meet people's needs and improve their lives. Read the comprehensive sustainability performance review.

Awards & recognition

Financial Reporting

Net sales for the Electrolux Group in 2013 amounted to SEK 109,151m, as against SEK 109,994m in the previous year. The organic sales growth was 4.5%, while currencies had an impact of -5.3%.