ENVIRONMENT

MANAGEMENT APPROACH

Electrolux applies a product lifecycle approach to managing environmental impacts. Factories, warehouses and offices have processes in place to manage risks and integrate environmental priorities.

Achievements and objectives

For 2013 achievements and future objectives, see performance reviews for Products, markets and services, People and operations (Efficiency) and Stakeholders and society (Responsible sourcing), the latter covers work with suppliers.

Roles and responsibilities

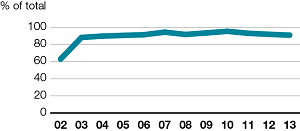

Each business area is required by Group Management to implement an environmental management system throughout its operations. The system is built on the Environmental Policy, Workplace Standard (the Group’s guidelines on how to meet Electrolux sustainability-related codes and policies) and ISO14001 certification. All manufacturing units of over 50 people must be certified to ISO14001, and newly acquired units are required to complete the certification process within three years of acquisition. Today, 91 % of applicable operations are certified according to ISO14001.

ISO14001 certification

As of 2013, the global ISO certification program for environment and quality encompasses annual audits of all manufacturing facilities, with recertification audits every third year. For selected sites, the audits also cover OHSAs for health and safety. In addition to certification, performance against the environmental as well as health and safety provisions set out in the Electrolux Workplace Standard was monitored. The approach is expected to deliver improved governance and reporting, as well as greater harmonization across the Group.

Operational responsibility

Electrolux Sustainability Affairs, a Group staff function, is responsible for driving and monitoring environmental performance group-wide, as well as public disclosure. It co-ordinates environmental reduction targets at the operational level as well as carbon emissions relating to transportation.

The Electrolux Manufacturing System (EMS) is a program to implement lean production that covers global manufacturing facilities for both major and small appliances. In addition, EMS is used for monitoring and eliminating waste and increasing safety and quality within production processes.

The Green Spirit program is an integral part of the EMS. Objectives are set to continuously reduce resource consumption, waste and emissions. The Green Spirit initiative includes energy management, technological investments, employee awareness raising and behavior change. Energy-saving targets are implemented in offices, factories and warehouses through the program.

Priorities

During 2013, the focus was on:

- Developing the Electrolux 2020 carbon target

- Setting new water reduction targets for Group manufacturing sites

- Implementing a carbon calculator for transport emissions for major markets

- Developing a reporting process for product performance as well as an online reporting and management tool for sustainability performance

- Group-wide roll-out of a certification program for environment, quality and health and safety based on ISO and OHSAS.

Materials

Material use is collated on a site-by-site basis during the annual Environmental Performance Assessment. The site manager is responsible for sending data to Sustainability Affairs. Continuous reduction in material use is driven through ISO14001.

Energy

Energy use and CO2 emissions are the highest priorities for resource efficiency. As part of the sustainability strategy, Electrolux is reducing energy impacts and engaging in climate-related issues. During 2013 Electrolux was included in CDP’s (formerly known as Carbon Disclosure Project) index for Transparency and its index for Actions to mitigate the risks of climate change.

The 2020 carbon target

During 2013 Electrolux committed to a carbon target. The Group will cut its CO2 impact by 50% by 2020 relative to 2005 production levels. Approximately 25 million tonnes will be cut in emissions deriving from product use, use of high global warming potential greenhouse gases, in production and in transportation.

Electrolux commissioned a third party energy, climate and carbon specialist to review the process for developing the carbon target and the program for its delivery. These were considered sound.

A focus for 2014 will be to kick off engagement with employees around the carbon target.

To achieve its carbon target Electrolux is:

- Setting efficiency targets for products

- Eliminating greenhouse gases with a high global warming potential

- Reducing energy use in operations

- Increasing carbon efficiency in transporting Electrolux products

- Raising awareness of the importance of energy-efficient products.

The Group’s most relevant climate-related issue is the energy needed by consumers using Electrolux products. To achieve its new carbon target, Group products must be among the leaders in energy efficiency in each product segment and market. The Group aims to expand the market for energy-smart products by influencing consumer purchasing through marketing, communications and public policy work.

Eliminating greenhouse gases used in products with a global warming potential higher than 15 is a key part of the target.

The Group’s approach to green product innovation and design is outlined further under Products and services.

Target achievement in factories is monitored by Group Sustainability Affairs and reported to management and through the Electrolux Manufacturing System (EMS). Leaner manufacturing is an important aspect of the sustainability strategy. The Green Spirit’s 2020 program is to reduce energy consumption by more than 50%.

As a first step to reducing CO2 impact of transportation, a group-wide system for gathering and tracking transport data is under implementation. A new target for 2015 will be set, and the result from 2013 will be used as a new baseline.

Factory-focus

Approach

Green Spirit focuses on environmental performance improvement and employee engagement through practical involvement. Electrolux continues to focus on energy use and carbon emissions in manufacturing. Both relative and absolute targets have been set. As part of the Group’s 2020 50% carbon reduction target, a series of shorter-term energy-saving targets have been set in factories, offices and warehouses. Each facility gathers energy and water consumption data and reports on a monthly basis to Sustainability Affairs where data is collated. Best practice examples are shared across the Group. Waste and emissions targets are under development.

Green Spirit information points in facilities keep employees up to date on progress against targets. Suggestions from employees for environmental improvement are encouraged and rewarded.

Green Spirit certification

Criteria for attaining Green Spirit certification levels have been raised. For example, a factory aiming for the silver standard today must pass new requirements to maintain its silver status in the upcoming year.

Performance

During 2013, the focus of Green Spirit across the Group was on working towards the target to reduce energy use by 15% by 2015, based on 2011 production volumes.

Electrolux is on track to achieve the 2015 energy reduction target and in 2013 the Group achieved a 10% relative improvement in comparable factories making finished products compared to 2011. In absolute terms the Group increased its energy use by 11% due to acquisitions and the start-up of new factories.

The average energy consumption per unit produced in comparable factories has decreased by 21% during the last five years.

Improved energy efficiency is saving more than SEK 300m a year in energy costs and emitting 200,000 tonnes less carbon dioxide compared to 2005.

In 2013, 11 factories achieved gold Green Spirit certification and 2 the platinum (highest) level.

Green Spirit goals for 2014 include:

- Implement the 2014-2015 energy action plans

- Increase in the number of factories certified to the new gold and platinum level

- Introduce new waste and emissions targets

- Continue to support new and recently acquired sites taking up the Green Spirit program.

Work will also continue on reducing emissions from transport and water use as described in the transport and water sections below.

Engagement with suppliers

Through the Workplace Standard, Electrolux requests that all suppliers measure and monitor their energy use. Electrolux launched its energy-reporting standard, based on GRI criteria, among OEM (original equipment manufacturing) and ODM (original design manufacturing) suppliers. At present, supplier energy consumption is not integrated into the Group’s external reporting of energy use.

During 2013, Electrolux collected data from approximately 60% of the Group’s OEM supplier spend on their environmental performance. In 2014, the share is expected to rise to 70%.

Transportation

The implementation of the group-wide system for gathering and tracking transport data continued. Information collected by sectors is reported to Group level for monitoring. Based on the results from 2013, the target will be revised to reflect the improvement in data accuracy. A new target for 2015 will be set, and the result from 2013 will be used as a new baseline.

The Electrolux Global Ocean Team has partnered with Business for Social Responsibility’s Clean Cargo Working Group to standardize calculations for emissions on ocean-going cargo and drive CO2 reductions from ocean shipments. Overall Electrolux achieved improved carbon efficiency of more than 20% between 2010 and 2013 in its ocean transportation.

Group emissions from transport in 2013 was 420,000 tonnes of CO2, slightly lower than the year previous. This is mainly due to CO2 reductions in ocean transportation.

Water

Electrolux continues its support of the UNGC Water Mandate. Its Communication on Progress is included in this GRI report.

Electrolux defined a reduction target for water use of 20% by 2014, using 2010 as a baseline and this was achieved two years ahead of schedule. Water consumption in factories is managed under Green Spirit, using the same approach as the energy-savings target to compile and share water data across the Group. Performance is monitored on a monthly basis through the Green Spirit program.

Together with WWF, Electrolux mapped water-related risks associated with Group factories. As a result, new and more stringent targets have been set in 2013 for factories in water-stressed areas.

Electrolux engages with local authorities on issues such as water availability in regions where production facilities are located. Water availability is a local issue and raising awareness among employees is an important part of achieving water reductions.

The Green Spirit program engages employees in local savings initiatives. The company also has ongoing dialog with factory suppliers on how to improve processes for better water performance. Electrolux operations will continue to increase investment in innovation for water-efficient products and improve its processes in the area of assessing and monitoring water management.

Continuous improvement in water management is outlined as an expectation in the Workplace Standard and Environmental Policy and is mandatory for all suppliers.

In 2013, Electrolux launched YourWaterMark to engage consumers worldwide in consumer impacts on water resources. Facebook users were able to test their water use and taken action.

Biodiversity

Biodiversity management is not deemed a material issue for the Group. Biodiversity issues are managed locally. Group-wide general guidelines as outlined in the Workplace Standard describe the methodology that should be applied in issues such as biodiversity. Two facilities (Solaro, Italy and Revin, France) are adjacent to protected biodiversity areas. Electrolux monitors all its facilities for emissions and no significant impacts on biodiversity have been identified.

Emissions, effluents and waste

All hazardous waste (oils, solvents and other chemicals) is managed in accordance with local regulations.

Products and services

Sustainability Affairs is responsible for promoting the climate change agenda with stakeholders, as well as raising awareness of the role of energy and water-efficient appliances in reducing consumers’ carbon footprint.

To meet the Electrolux 50% carbon reduction target by 2020, the design and development of products with increased efficiency is a top priority. Electrolux is setting efficiency targets for products. To achieve these, Group products must be among the leaders in energy efficiency in each product segment and market.

At the outset, the target will apply to products within the kitchen, laundry and small appliances ranges. As methodologies evolve, Electrolux will extend the target to more products and regions.

During 2013 Electrolux progressed a global reporting platform to enable more comprehensive product efficiency disclosure.

Each business sector within Electrolux promotes its range of water- and energy-efficient products. Electrolux raises the bar for products qualifying for the Green Range on a yearly basis. The criteria are based on environmental parameters defined by the Group and are defined to reflect regional market need.

The company’s designers are trained on the Product Management Flow, which includes an integrated sustainability analysis tool to ensure that potential sustainability issues are addressed in product development. Information is shared and responsibility for sustainability is assigned to the Project Manager.

Letter of the law

Electrolux is also preparing for increased legislation worldwide on managing chemicals, energy efficiency standards and producer responsibility for recycling of Group appliances in all markets.

REACH is an EU regulation on the registration, evaluation, authorization and restriction of chemicals. Electrolux sees REACH as a tool for ensuring safe products, safe production and environmental protection.

Electrolux in Europe has a central chemical office to effectively manage chemicals regulation such as REACH, and continuously adds new chemicals to its Restricted Materials List of targeted substances for elimination. Electrolux will build on its experience during 2014, when it will set up a global office to co-ordinate and manage chemicals legislation and use across the Group.

StopSearchHereCEO Statement

In 2013 we continued to deliver above our growth target and delivered 4.5% in organic sales growth.

CEO Statement

I'm convinced that raising product efficiency for the growing middle class is where long-term shareholder value creation lies.

Our products

Electrolux is the only appliance manufacturer in the industry to offer complete solutions for both consumers and professionals. The focus is on innovative and energy-efficient products in the premium segments.

Sustainability

Achieving the Group's vision of sustainability leadership is crucial to realizing the business strategy. The objective is to develop smarter, more accessible, resource-efficient solutions that meet people's needs and improve their lives. Read the comprehensive sustainability performance review.

Awards & recognition

Financial Reporting

Net sales for the Electrolux Group in 2013 amounted to SEK 109,151m, as against SEK 109,994m in the previous year. The organic sales growth was 4.5%, while currencies had an impact of -5.3%.