The Group’s major markets were characterized by considerable uncertainty in 2011. Raw-material prices continued to rise and price pressure prevailed in the Group’s major markets.

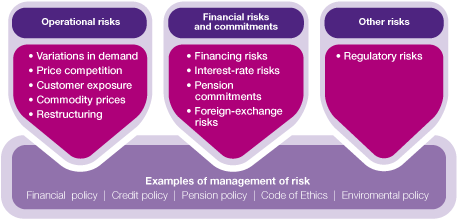

In general, there are three types of risks: Operational risks, which are normally managed by the Group’s operational units; financial risks, which are managed by Group Treasury; and other risks.

Electrolux monitors and minimizes key risks in a structured and proactive manner. Capacity has been adjusted in response to weak demand, working capital has undergone structural improvements, the focus on price has intensified and the purchasing process for raw materials has been further streamlined. The diagram above describes the major risks and the Group’s response in order to manage and minimize them.

Operational risks

The Group’s ability to improve profitability and increase shareholder return is based on three elements: innovative products, strong brands and cost-efficient operations. Realizing this potential requires effective and controlled risk management. The major risks at present are described below.

Fluctuation in demand

In 2011, demand for appliances declined in the major markets of Electrolux. The North American market contracted by 4% during the year. In Europe, demand in the West declined by 3%, while it grew by 9% in the East. In Latin America, growth diminished in Brazil towards the latter part of the year. In the Asia/Pacific region, demand in Australia increased due to high growth of air-conditioning equipment and the Asian markets continued to grow healthily.

Weak demand in earlier years resulted in Electrolux operations being run at an average of 60% capacity. Decisive actions and savings packages throughout the Group have proven that Electrolux can quickly adjust its cost structure when demand for the Group’s products declines.

Price competition

Most of the markets served by Electrolux are experiencing strong price competition. This is particularly severe in the low-price segments and in product categories with a great deal of overcapacity. In 2011, pressure on prices was evident in the Group’s major markets. Sales promotion continued in the North American market at the same time as prices declined continuously during the year in Europe. To offset the intense price pressure, Electrolux carried out two price increases in North America in 2011. Further price hikes have been announced in North America and Europe for early 2012. Price pressure also prevailed in Australia.

Exposure to customers and suppliers

The weak trend in the major Electrolux markets in 2011 impacted the Group’s retailers who experienced difficult trading conditions but this did not result in any increases in credit losses for Electrolux.

Electrolux has a comprehensive process for evaluating credits and tracking the financial situation of retailers. Management of credits as well as responsibility and authority for approving credit decisions are regulated by the Group’s credit policy. Credit insurance is used in specific cases to reduce credit risks.

Raw materials and components represent the largest cost item

Materials account for a large share of the Group’s costs. In 2011, Electrolux purchased raw materials and components for approximately SEK 41 billion, of which approximately SEK 20 billion referred to the former. The Group’s exposure to raw materials comprises mainly steel, plastics, copper and aluminum.

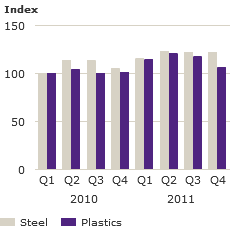

Market prices of raw materials rose in the early part of 2011. Following this initial rise, market prices declined towards the end of the year. Electrolux utilizes bilateral contracts to manage risks related to steel prices. Some raw materials are purchased at spot prices. The total cost of raw materials in 2011 was approximately SEK 2 billion higher than in 2010. The total cost of raw materials in SEK was, however, in line with the previous year due to lower purchased volumes and weaker USD and EUR relative to SEK.

Restructuring for competitive production

A large share of the Group’s production has been moved from high-cost to low-cost areas. Restructuring is a complex process that requires managing a number of different activities and risks. Increased costs related to relocation of production can affect income in specific quarters. When relocating, Electrolux is also dependent on the capacity of suppliers for cost-efficient delivery of components and semi-finished goods.

The restructuring program was launched in 2004. The total cost of the program is approximately SEK 11.7 billion and it will generate annual savings of approximately SEK 4.6 billion compared with the base year 2004.

Financial risks and commitments

The Group’s financial risks are regulated in accordance with the financial policy that has been adopted by Electrolux Board of Directors. Management of these risks is centralized to Group Treasury and is mainly based on financial instruments. Additional details regarding accounting principles, risk management and risk exposure are given in Notes 1, 2 and 18.

Financing risk

For long-term borrowings, the Group’s goal is to have an average maturity of at least two years, an even spread of maturities and an average fixed-interest period of one year. At year-end 2011, Group borrowings amounted to SEK 14,206m, of which SEK 11,669m referred to long-term loans with an average maturity of 3.0 years. Loans are raised primarily in EUR and SEK. The average interest rate at year-end for the total borrowings was 3.7%. At year-end 2011, the average fixed-interest period for long-term borrowings was 1.2 years. Long-term loans totaling approximately SEK 4,100m will mature in 2012 and 2013. Liquid funds on December 31, 2011, amounted to SEK 7,839m.

In addition, the Group has two unutilized credit facilities; Since 2010, Electrolux has an unused committed multicurrency revolving credit facility of SEK 3,400m maturing 2017. In December 2011 an unused committed multicurrency revolving credit facility from 2005, of EUR 500m, with maturity in 2012, was replaced. The new committed multicurrency revolving credit facility of EUR 500m maturing 2016 has an extension option for up to two more years.

On the basis of the volume of loans and the interest-rate periods in 2011, a change of 1 percentage point in interest rates would affect Group income in the amount of +/– SEK 60m. For additional information on loans, see Notes 2 and 18.

Pension commitments

At year-end 2011, Electrolux had commitments for pensions and benefits that amounted to approximately SEK 24 billion.

The Group manages through pension funds pension assets of approximately SEK 20 billion. At year-end, approximately 35% of these assets were invested in equities, 47% in bonds, and 18% in other assets.

Net provisions for post-employment benefits amounted to SEK 287m.

Yearly changes in the value of assets and commitments depend primarily on developments in the interest-rate market and on stock exchanges. Other factors that affect pension commitments include revised assumptions regarding average life expectancy and healthcare costs.

Costs for pensions and benefits are recognized in the income statement for 2011 in the amount of SEK 425m. In the interest of accurate control and cost-effective management, the Group’s pension commitments are managed centrally by Group Treasury. Electrolux uses interest-rate derivatives to hedge parts of the risks related to pensions. For additional information, see Note 22.