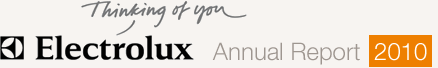

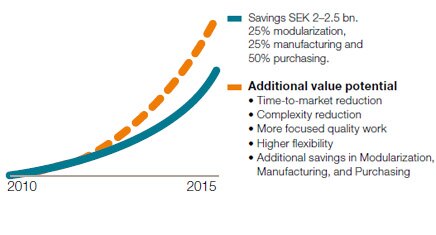

Having achieved a competitive production structure, a strong global brand and a profitable process for consumer-driven product development, the next step in the Group´s efficiency program is ready to be taken. Global initiatives will enable Electrolux to continue to reduce costs by drawing on the advantages provided by the global strength and reach of the Group. This will be achieved through leveraging synergies within modularization, manufacturing and procurement. The total estimated savings provided by the initiative amount to approximately SEK 2–2.5 billion per year and full effect will be achieved in 2015. The initiatives will further strengthen the competitiveness of Electrolux and lead to increased speed and precision in product launches for the mass-market and premium segments; thus contributing to profitable growth. The cost of these global initiatives is estimated to amount to approximately SEK 500m per year during 2011 and 2012.

Value creation from global operations

Greater production synergies

Electrolux possesses the prerequisites to achieve even greater economies of scale at its production units throughout the world. Above all, it is crucial to reduce complexity by defining the optimal structure and coordinating manufacture of the various products. Focus is placed on creating a swift and efficient process for component assembly.

Optimized procurement

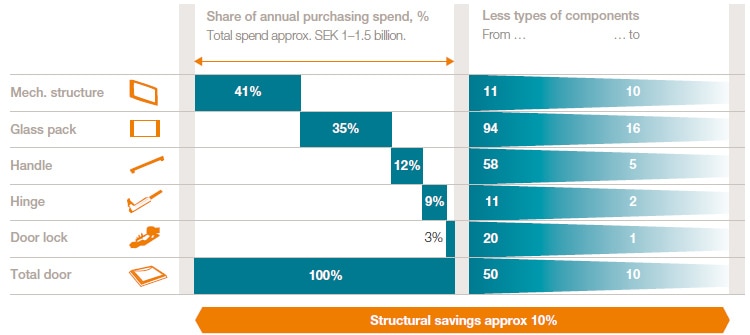

Approximately half of the savings delivered by the global initiatives are expected to be realized through better global coordination of procurement. Modules with standardized interfaces, products and components result in fewer suppliers while increasing the volume of the input goods being procured. Another prioritized area that is part of delivering greater efficiency is the involvement of the procurement function earlier in the product development process.

Faster and more efficient product development

Developing products based on global needs leads to greater efficiency not only in product development and marketing, but also in production, since fewer product platforms are required. Cooperation between the different Electrolux global product councils for appliances will accelerate, and global units for product development in the respective product categories will accelerate the pace of innovation. Currently, Electrolux has eight global product development centers for household appliances around the world that focus on areas including induction, built-in and front-loaded washing machines. The objective is to further increase the level of differentiation for new launches in the premium segment and concurrently be able to profitably compete in the mass-market segment.

Utilizing global strength with consumer focus

Modularization

Standardizing and utilizing modules for components common to all products, in one category, facilitates faster product development and more rapid satisfaction of consumer needs. In addition, procurement costs are reduced; resulting, for example, in lower product costs. In appliances, work is ongoing to identify the number of variants needed for a product category’s various components, such as glass shelves, handles and hinges. Although criteria for design must be varied to meet consumer preferences and tastes, the inside of the product is rarely affected.

Example of modularization, oven door