The operations of Electrolux are exposed to a number of strong external factors that affect the Group’s opportunities to increase profitability and return, and thus its ability to achieve the Group’s financial goals.

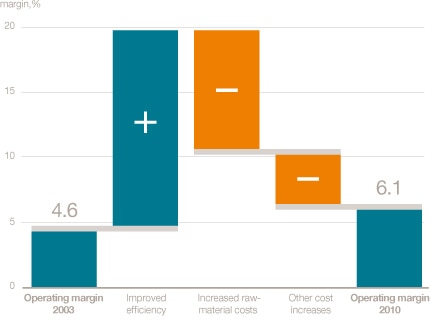

Rising raw-material costs have been offset by improvements

Electrolux can manage long-term, rising raw- material costs through cost-cutting measures, price increases and an improved product mix. Since 2004, raw-material costs have increased by approximately SEK 9 billion. At the same time investments in brand marketing and product development have increased. Higher costs for raw materials have been compensated for, among other things, by efficiencies within manufacturing and purchasing. Operating margin, excluding items affecting comparability has improved from 4.6% in 2003 to 6.1% in 2010.

Raw-material costs

Raw materials account for a large share of the Group’s costs. In 2010, Electrolux purchased components and raw materials for approximately SEK 44 billion, of which raw materials represented approximately SEK 20 billion. The raw materials to which the Group is primarily exposed comprise steel, plastics, copper and aluminum. Raw-material prices rose sharply in 2004–2008, which resulted in an increase of SEK 9 billion in the Group’s costs. In light of the highly competitive nature of the market, mainly cost savings were used to offset the increase in the cost of raw materials. Following a decline in the second half of 2008 and beginning of 2009, prices of raw materials began to rise again. In 2010, the cost of raw materials rose by SEK 1.1 billion for Electrolux, and in 2011 the increase is expected to be SEK 1.5 – 2.0 billion.

Electrolux can manage long-term, rising raw-material costs through cost-cutting measures, price increases and an improved product mix. However, adjusting operations in the short-term in response to substantial, rapid price movements is more challenging. Electrolux prefers a steady increase in price over a longer period rather than volatile movements that substantially increase or decrease prices.

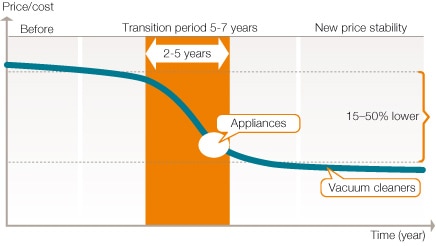

Prices and overcapacity

Strong downward pressure on prices has been evident in most of the Group’s markets for a number of years. Price competition has been particularly severe in low-price segments and in product segments where there is substantial overcapacity as well as in markets with low levels of consolidation. In Europe, where prices have been declining for several years, many producers were able to defend and raise prices in 2009 despite weak demand and a fragmented market. In 2010, price pressure was again intensified, partly driven by changes in exchange rates. In light of the comprehensive relocation of production to low-cost areas during the past decade, most producers have similar cost levels today. In addition, rates of capital intensity in the industry are relatively low, which facilitates rapid adaptation of production for manufacturers. The industry’s structural overcapacity always implies a risk of short-term downward price pressure due to manufacturers choosing to increase production to capture market shares through lower prices. For example, in North America, extensive price campaigns for washing machines resulted in downward price pressure in the segment in 2010.

The vacuum-cleaner industry, which has seen a greater degree of transformation than appliances, does not suffer from the same price-deflation. Consumers are prepared to pay higher prices for new functions and intelligent design.

Electrolux, as one of the few global manufacturers of appliances and vacuum cleaners, has the opportunity to optimize production and procurement on a global basis, thus creating scope to continue reducing costs.

The vacuum cleaner industry has reached price stability. Major appliances is in an earlier stage of the change process.

Demand trends

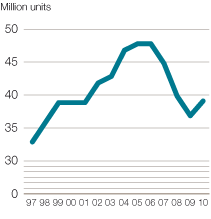

Demand for appliances is primarily dependent on general business conditions. Since Electrolux is a producer of consumer goods, sales are affected at an early stage in the economic cycle. Lower market demand can lead not only to lower sales volumes, but also to a shift in demand to products with lower prices and margins. In addition, utilization of production capacity declines in the short term. A stronger global economy contributed to the rise in demand in most markets during 2010. In the US, during the second quarter, the federal rebate program to promote the purchase of energy-efficient household appliances resulted in many households bringing forward their planned purchases of appliances. Demand grew strongly during the first six months to then stabilize during the second half of the year. In the growth markets of Latin America, Asia and Eastern Europe, demand accelerated off the back of the rapid growth of a affluent middle class. Demand in the mature markets of Western Europe and Australia was unchanged or declined somewhat. As a result of high penetration in the majority of product categories in Western markets, in combination with a historic low demand, sales are becoming increasingly dependent on households replacing their old products with new. Replacement products accounted for approximately 75% of sales of household appliances in the US during 2010.

Specific segments such as frost-free freezers and induction hobs show continued strong growth, irrespective of market. Governmental incentives for stimulating consumer purchases of energy- and water-efficient household appliances have been implemented in several countries, including Brazil, the US and Australia. Electrolux has a leading position in this segment, and can benefit from increased demand.