Demand stabilized in the Group’s major markets during 2010. Access to credit also improved after a period of turbulence in the financial markets. However, volatile patterns in raw-material prices and downward price pressure prevailed in the Group’s major markets.

Electrolux monitors and minimizes key risks in a structured and proactive manner. Capacity has previously been adjusted in response to weak demand, working capital has undergone structural improvements, the focus on price has intensified and the purchasing process for raw materials has been further streamlined. The diagram below describes the major risks and the Group’s response in order to manage and minimize them.

In general, there are three types of risks: Business risks, which are normally managed by the Group’s operational units; financial risks, which are handled by Group Treasury; and other risks.

Business risks

The Group’s ability to improve profitability and increase shareholder return is based on three elements: innovative products, strong brands and cost-efficient operations. Realizing this potential requires effective and controlled risk management. The major risks at present are described below.

Fluctuations in demand

In 2010, demand for appliances stabilized in the major markets of Electrolux. Following three years of recession (2006–2009), the North American market grew by 5% in 2010. In Europe, demand increased somewhat in Western Europe (1%), while Eastern Europe – after a period of deep recession – grew by 6%, albeit from low levels. In Latin America, growth diminished in Brazil after the stimulus package ended, while other markets grew strongly. In the Asia/Pacific region, the Australian market stabilized and the Asian markets continued to grow healthily.

Weak demand in earlier years has resulted in Electrolux operations being run at an average of 60% capacity. Despite this, the Group successfully achieved an operating margin in excess of 6%, excluding items affecting comparability. Decisive actions and savings packages throughout the Group have proven that Electrolux can quickly adjust its cost structure when demand for the Group’s products declines.

Price competition

Most of the markets in which Electrolux operates feature strong price competition. This is particularly severe in the low-price segments and in product categories with large over-capacity.

During the year, pressure on prices increased in the Group’s major markets. A government subsidization program for green products led to greater volatility in demand in North America. The subsidization program generated increased demand during the second quarter. When the subsidization program expired, demand declined in the third quarter, which led to higher inventory levels among producers and retailers. To maintain demand and to reduce inventory levels, campaign-driven price promotions were introduced. In Europe, prices also fell, primarily in Russia, Southern Europe and the Nordic region. Price pressure also prevailed in Australia.

Exposure to customers and suppliers

After a number of years of recession and uncertainty in the financial markets, the situation stabilized for the Group’s retailers and suppliers in 2010.

Quelle of Germany, one of the Group’s major retailers, went into bankruptcy in the fourth quarter of 2009. This reduced the Group’s sales of appliances under private labels. New sales of appliances to IKEA in Europe partly offset the decline in volumes.

Electrolux has a comprehensive process for evaluating credits and tracking the financial situation of retailers. Management of credits as well as responsibility and authority for approving credit decisions are regulated by the Group’s credit policy. Credit insurance is used in specific cases to reduce credit risks.

Raw materials and components account for most costs

A large share of the Group’s costs refers to materials. In 2010, Electrolux purchased raw materials and components for approximately SEK 44 billion, of which approximately SEK 20 billion referred to the former. The Group’s exposure to raw materials comprises of mainly steel, plastics, copper and aluminum.

Market prices of raw materials increased in the first half of 2010. In the second half of the year, market prices of steel initially declined before climbing again towards the end of the period. Electrolux uses bilateral contracts to manage risks related to steel prices. Some raw materials are purchased at spot prices. The total cost of raw materials in 2010 was approximately SEK 1 billion higher than in 2009.

Restructuring for competitive production

A large share of the Group’s production has been moved from high-cost to low-cost areas. The restructuring program was launched in 2004. The remaining costs for this program are expected to be taken in 2011. The total cost of the program is approximately SEK 8.5 billion and it will generate annual savings of approximately SEK 3.4 billion compared with the starting position in 2004.

Restructuring is a complex process that requires managing a number of different activities and risks. Increased costs related to relocation of production can affect income in specific quarterly periods. When relocating, Electrolux will also be dependent on the capacity of suppliers for cost-efficient delivery of components and half-finished goods.

Financial risks and commitments

The Group’s financial risks are regulated in accordance with the financial policy that has been adopted by the Board of Directors. Management of these risks is centralized to Group Treasury and is based for the most part on financial instruments. Additional details regarding accounting principles, risk management and risk exposure are given in Notes 1, 2 and 18.

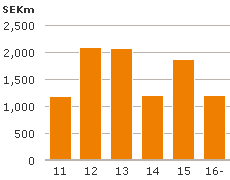

Financing risk

For long-term borrowings, the Group’s goal is to have an average maturity of at least two years, an even spread of maturities and an average fixed-interest period of one year. At year-end 2010, Group borrowings amounted to SEK 12,096m, of which SEK 9,590m referred to long-term loans with an average maturity of 3.3 years. Loans are raised primarily in EUR and SEK. The average interest rate at year-end for the total borrowings was 3.2%. At year-end 2010, the average interest-fixing period for long-term borrowings was 0.9 years. Long-term loans totaling approximately SEK 3,300m will mature in 2011 and 2012. Liquid funds as of December 31, 2010, amounted to SEK 12,805m.

In addition, the Group has two unutilized credit facilities; the first totaling EUR 500m with a term of seven years maturing in 2012, and the second totaling SEK 3.4 billion with a term of seven years maturing in 2017. On the basis of the volume of loans and the interest-rate periods in 2010, a change of 1 percentage point in interest rates would affect Group income in the amount of +/– SEK 60m. For additional information on loans, see Notes 2 and 18.

Pension commitments

At year-end 2010, Electrolux had commitments for pensions and benefits that amounted to approximately SEK 22 billion.

The Group manages pension assets of approximately SEK 19 billion. At year-end, approximately 42% of these assets were invested in equities, 41% in bonds, and 17% in other assets.

Net provisions for post-employment benefits amounted to SEK 957m.

Yearly changes in the value of assets and commitments depend primarily on developments in the interest-rate market and on stock exchanges. Other factors that affect pension commitments include revised assumptions regarding average life expectancy and healthcare costs.

Costs for pensions and benefits are reported in the income statement for 2010 in the amount of SEK 741m. In the interest of accurate control and cost-effective management, the Group’s pension commitments are handled centrally by Group Treasury. Electrolux uses interest-rate derivatives to hedge parts of the risks related to pensions. For additional information, see Note 22.