2015 was characterized by a year of positive development in core markets, while the environment in emerging markets was uncertain with a high level of fluctuations in currency rates. Electrolux monitors and manages its exposure to various types of risks in a structured and proactive manner.

Variations in demand

Price competition

Customer exposure

Commodity prices

Restructuring

Financing risks

Interest-rate risks

Pension commitments

Foreign-exchange risks

Regulatory risks

Reputational risk

In general, there are three types of risks: Operational risks, which are normally managed by the Group’s operational units; Financial risks, which are managed by Group Treasury; and Other risks.

Financial policy | Credit policy | Pension policy | Code of Ethics | Environmental policy

Electrolux monitors and minimizes key risks in a structured and proactive manner. Over the years, capacity has been adjusted in response to demand, working capital has undergone structural improvements, the focus on price and mix has intensified and the purchasing process for raw materials has been further streamlined. The major risks and the Group’s response in order to manage and minimize them are described below.

The Group’s ability to improve profitability and increase shareholder return is based on three elements: innovative products, strong brands and cost-efficient operations. Realizing this potential requires effective and controlled risk management.

Market demand for core appliances in Western Europe increased by 5% in 2015. Most markets in Eastern Europe also increased but the overall demand declined by 17% impacted by continued decline in Russia. In total, the European market increased by 4% excluding Russia. Market demand for core appliances in North America increased by 6%. Market demand for core appliances in Australia increased, while demand in China and Southeast Asia declined. Demand for appliances in Brazil continued to deteriorate while some other markets such as Argentina increased.

In times of weak markets and decline of demand for the Group’s products, decisive actions and savings packages throughout the Group have proven that Electrolux can quickly adjust its cost structure.

A number of the Electrolux markets are experiencing price competition. This is particularly evident in the low-cost segments and in product categories with a great deal of overcapacity. In 2015, prices continued to be under pressure in some of the Group’s major markets in Europe. In Latin America, high inflation combined with currency rate fluctuations resulted in Electrolux carrying out several price increases to offset the negative effect.

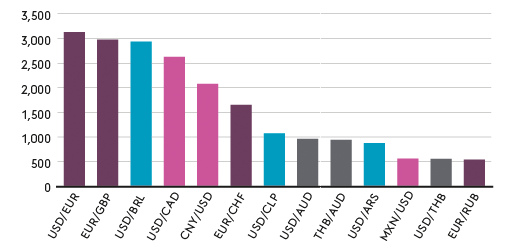

| Risk | Change +/- | Pre-tax earnings impact, SEKm |

|---|---|---|

| Raw materials1) | ||

| Steel | 10% | 800 |

| Plastics | 10% | 700 |

| Currency2) and interest rates | ||

| USD to BRL | 10% | 270 |

| USD to EUR | 10% | 230 |

| USD to CAD | 10% | 180 |

| EUR to GBP | 10% | 170 |

| EUR to CHF | 10% | 100 |

| USD to CLP | 10% | 80 |

| USD to ARS | 10% | 80 |

| THB to AUD | 10% | 80 |

| USD to AUD | 10% | 70 |

| EUR to RUB | 10% | 50 |

| Translation exposure to SEK3) | 10% | 260 |

| Interest rate | 1 percentage point | 20 |

1) Changes in raw materials refer to Electrolux prices and contracts, which may differ from market prices. 2) Includes transaction effects. 3) Assuming the Swedish krona appreciates/depreciates against all other currencies

| SEK bn | |

|---|---|

| Revenues | 124 |

| Direct material | –48 |

| Sourced products | –17 |

| Salaries and other expenses1) | –54 |

| Operating income | 5 |

| Variable cost to sales | 77% |

| Fixed cost to sales | 19% |

| Operating margin | 4% |

The trading conditions for retailers in 2015 were challenging in some markets such as Brazil and some Eastern European countries. Retailers in Western Europe and the U.S. showed a slight improvement compared to the previous year.

Electrolux has a comprehensive process for evaluating credits and monitoring the financial situation of customers. Authority for approving and responsibility to manage credit limits are regulated by the Group’s credit policy. A global credit insurance program is in place for many countries to reduce credit risk.

For more information, see Note 2 and Note 17.

Materials account for a large share of the Group’s costs. In 2015, Electrolux purchased raw materials and components for approximately SEK 48bn, of which approximately SEK 18bn referred to the former. The Group’s exposure to raw materials comprises mainly steel, plastics, copper and aluminum.

Market prices for raw materials were under pressure during the year and steel prices and prices for plastics declined. Electrolux purchases of commodities and components are to a large extent managed through bilateral contracts. Some raw materials are purchased at market prices.

A large share of the Group’s production has been moved from high-cost to low-cost areas. Restructuring is a complex process that requires managing a number of different activities and risks. Increased costs related to relocation of production can affect income in specific quarters. When relocating, Electrolux is also dependent on the capacity of suppliers for cost-efficient delivery of components and semi-finished goods.

The major restructuring programs are in its final stages. Although there will likely be restructuring programs going forward, these are expected to be much less extensive.

The Group’s financial risks are regulated in accordance with the financial policy that has been adopted by the Electrolux Board of Directors. Management of these risks is centralized to Group Treasury and is mainly based on financial instruments. Additional details regarding accounting principles, risk management and risk exposure are given in Notes 1, 2 and 18.

For long-term borrowings, the Group’s goal is to have an average maturity of at least two years, an even spread of maturities and an average fixed-interest period of one to three years.

Long-term borrowings as of December 31, 2015, including long-term borrowings with maturities within 12 months, amounted to SEK 11,000m with average maturity of 2.8 years, compared to SEK 12,123 and 2.8 years at the end of 2014. The average fixed-interest period for long-term borrowings was 0.8 years. In 2016, long-term borrowings in the amount of SEK 2,677m will mature.

Liquid funds as of December 31, 2015, amounted to SEK 11,199m, excluding short-term back-up credit facilities. Electrolux has two unused committed back-up revolving credit facilities. One multicurrency facility of SEK 3,400m maturing in 2017 and one multicurrency facility of EUR 500m, approximately SEK 4,600m, maturing in 2018. Electrolux has also a committed revolving credit facility of USD 300m, approximately SEK 2,500m, maturing in 2018.

For additional information on loans, see Notes 2 and 18.

At year-end 2015, Electrolux had commitments for pensions and benefits that amounted to approximately SEK 29bn. Through pension funds, the Group manages pension assets of approximately SEK 24bn. At year-end, approximately 37% of these assets were invested in equities, 41% in bonds, and 22% in other assets. Net provisions for post-employment benefits amounted to SEK 4,906m.

Yearly changes in the value of assets and commitments depend primarily on developments in the interest-rate market and on stock exchanges.

Other factors that affect pension commitments include revised assumptions regarding average life expectancy and healthcare costs.

Costs for pensions and benefits are recognized in the income statement for 2015 in the amount of SEK 891m. In the interest of accurate control and cost-effective management, the Group’s pension commitments are managed centrally by Group Treasury.

For additional information, see Note 22.

Reputational, regulatory and sustainability risks can potentially impact Electrolux ability to successfully conduct business. There are a number of processes in place to control these risks such as internal and supplier auditing, environmental management and certification, the Ethics program and the safety management system. The regulatory environment is monitored in order to be prepared for changes that impact the business. The process to identify material sustainability issues is described in the Sustainability Report. available at www.electroluxgroup.com.

| Carbon steel, 35% | 35 |

| Plastics, 37% | 37 |

| Copper and aluminum, 7% | 7 |

| Stainless steel, 10% | 10 |

| Other, 11% | 11 |

Trend for steel and plastics prices, weighted market prices indexed

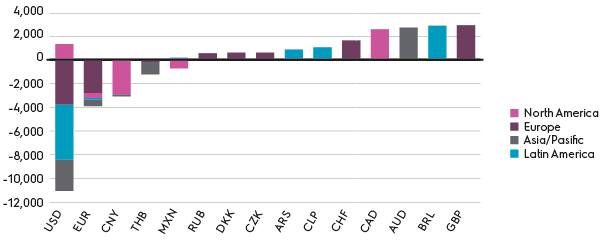

The global presence of Electrolux, with manufacturing and sales in a number of countries, offsets exchange rate effects to a certain degree. The principal exchange rate effect arises from transaction flows; when purchasing and/or production is/are carried out in one currency and sales occur in another currency. To some extent, the Group utilizes currency derivatives to hedge a portion of the currency exposure that arises. The business areas within Electrolux usually have a hedging horizon of between three and eight months of forecast flows. Hedging horizons outside this period are subject to approval. It is mainly business areas in emerging markets that have a shorter hedging horizon. The usual effect of currency hedging is that currency movements that occur today have, to a certain degree, a delayed effect. Electrolux is also affected by translation effects when the Group’s sales and costs are translated into SEK.

The translation exposure is primarily related to currencies in those regions where the Group’s most substantial operations exist, that is, EUR and USD.

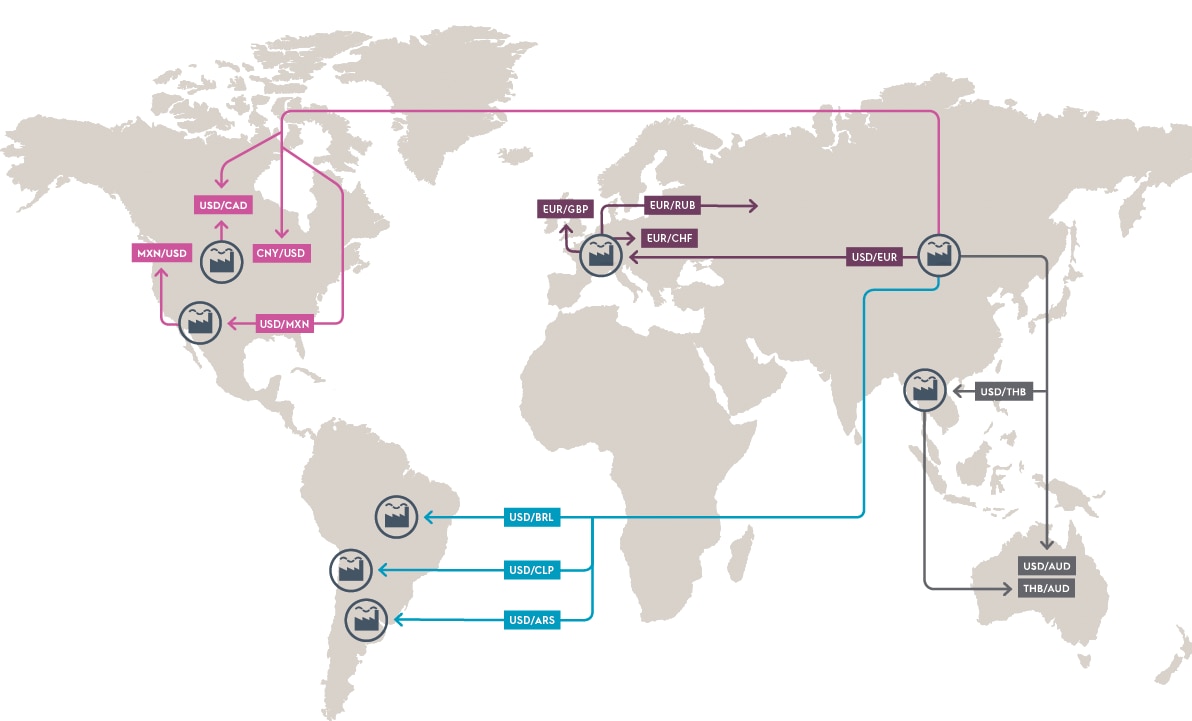

The major currencies for the Electrolux Group are the USD, EUR, BRL, CNY, GBP and CAD. The key currency pairs and flows are presented in the map together with an explanation of how they impact the Group. In general, income for Electrolux benefits from a weak USD and EUR and from a strong BRL, GBP, CAD and AUD.

In countries with large manufacturing and logistic centers, effects over time will to a large extent balance out due to natural hedging.

Compared with the previous year, changes in exchange rates for the full-year 2015 had a negative impact on operating income. The total currency effect (translation effects, transaction effects and net hedges) amounted to SEK –1,418m. The net transaction effect was SEK –1,873m and translation effects SEK +455m.

The impact from transaction was mainly attributable to the operations in Latin America and the strengthening of the USD against the BRL. The weakening of several currencies in emerging markets also impacted operations in Asia/Pacific and Europe, the Middle East and Africa. The negative impact of currencies on operating income was to a large extent mitigated by price increases and mix improvements.

A major part of the currency flows in Europe is denominated in Euro, with external imports in USD. Electrolux faces some currency exposure in Eastern European currencies when the cost base in local currencies in the factories differs from the domestic sales.

Electrolux is a net importer into the market with flows mainly from China and production conducted in Mexico. Since most imports are invoiced in USD, the currency exposure is limited. Canada is an exception as Electrolux imports products into that market.

Most of the finished products originates from own factories in the region, while input goods such as raw materials and components are to a large extent denominated in USD.

Electrolux sources input goods as well as finished goods to all global factories. A major part is invoiced in USD, but also in CNY.

Main import flows are based in USD, but there is also some exposure in THB from Electrolux factory in Thailand.

Main translation effects: USD/SEK, EUR/SEK.