Electrolux will make better use of resources by using more recycled materials, and helping to promote the market for recycling.

| The roadmap to 2020 | Next steps |

|---|---|

| Replace virgin materials with recycled materials in our products. |

|

| Adapt product design to further increase the use of recycled material. |

|

| Increase the volume of recycled plastic to 20,000 tonnes annually. |

|

| Increase amount of scrap based steel in our production. |

|

On track

Additional effort is required

Off track

Work has not yet begun

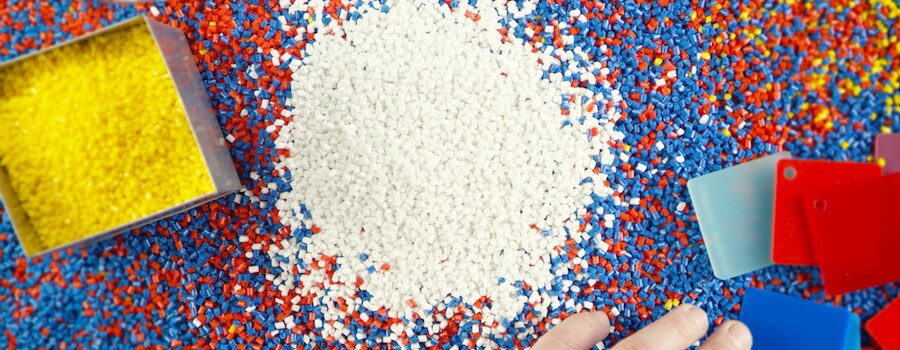

There is a continued growth of recycled plastic in Europe, with more potential identified in North and Latin America as well as in Asia-Pacific.

Our use of recycled plastics is rising steadily. From just over 6,000 tonnes in 2015, we reached about 7,400 tonnes in 2016. This is 20 times more than in 2011 when reporting started. Our objective for 2020 is to achieve 20,000 tonnes of recycled plastic per year. So far, the biggest shift has taken place in Europe, while we expect that our sectors in North America, Latin America and Asia Pacific will contribute more to the future increase.

Electrolux has developed applications for recycled plastics over the last five years - transforming post-consumer plastics into a high-quality plastic that is optimized for use in appliances. We are also exploring more complex applications, and redesigning components to suit recycled material.

Overcoming these challenges requires strategic partnerships with suppliers of recycled plastic and strong internal capabilities. Specific requirements have been added to the Electrolux Restricted Materials List, covering our restrictions on hazardous substances.

_2016_Tons of recycled plastic-.png)

| 2012 | 2014 | 2016 | 2018 | 2020 | |

| Growth of recycled plastics | 1407 | 4146 | 7389 | 14000 | 19948 |

Electrolux increased its use of recycled plastic by more than 50% per year on average since 2012, achieving 7,400 tonnes in 2016. The forecast is that we can reach about 20,000 tonnes annually by 2020. Solid line: performance up until 2016; dotted line forecast until 2020.

Carbon steel can be made from iron ore, steel scrap or a mix of the two. In addition to making use of scrap, recycled steel releases much less CO2 per tonnes produced. Electrolux has increased the amount of recycled steel from 7% in 2013 to 22% in 2016, which has reduced the average carbon emissions per tonnes of steel from 2.1 to 1.8 tonnes of CO2, and the total CO2 emissions by 170,000 tonnes.

1 We do not include polyurethan foam in the target since there are today no viable recycled alternatives for PU foam.